From Kitchen to Factory: A Practical Guide to Peanut Chikki Contract Manufacturing

India’s snacking market is rapidly expanding, driven by rising demand for clean-label, high-protein, and affordable indulgences. Peanut chikki, a heritage snack that’s both nutritious and shelf-stable, is perfectly positioned for this growth. But for most startups and food entrepreneurs, setting up a full-scale chikki plant from scratch isn’t feasible – it requires high capital, specialized equipment, and strict quality compliance. That’s why many F&B founders choose the smarter route: peanut chikki contract manufacturing.

By partnering with established peanut chikki contract manufacturing companies in India, brands can skip infrastructure hurdles and focus on R&D, marketing, and brand building – while experts handle production with industrial precision.

In this blog, we’ll explore how peanut chikki contract manufacturing works, what it costs, how to choose the right partner, and how Suite42 enables seamless product-to-market journeys for food brands across India.

An article that might interest you: Peanut Chikki Product Development in India: From Recipe Trials to Commercial Scaling

Why Food Brands Outsource Peanut Chikki Manufacturing

For a small or mid-scale food brand, outsourcing isn’t just cost-saving – it’s a strategic growth decision.

Top reasons food entrepreneurs prefer outsourcing include:

- Reduced Capital Expenditure:

Avoid ₹30–₹50 lakh investment in plant setup, machinery, and utilities. - Access to Expertise:

Contract manufacturers already understand process calibration, jaggery caramelization, and moisture control, reducing trial errors. - Speed to Market:

Scale from lab sample to full production in weeks, not months. - Regulatory Readiness:

Established plants follow FSSAI, ISO, and GMP standards, ensuring instant compliance. - Focus on Branding & Distribution:

Instead of managing production complexities, founders can focus on marketing, innovation, and sales.

Did you know? The organized traditional-sweets market in India grew by 14% CAGR (2020–2025), with peanut chikki among the top-performing categories in the clean-label snacking segment.

The Manufacturing Process – End to End

Professional peanut chikki contract manufacturing companies manage everything from ingredient sourcing to packaging.

Here’s how the full process flow works for F&B partners:

1. Product Development & Recipe Finalization

- Based on your target market (health, export, mass retail), R&D teams design an optimized formula.

- Process notes are created for peanut roasting temperature, jaggery Brix, and cutting size.

2. Raw Material Procurement

- Peanuts are sourced from Gujarat, Andhra Pradesh, or Maharashtra and checked for aflatoxin levels.

- Jaggery undergoes purity testing and moisture analysis.

3. Manufacturing & Quality Control

- Fully automated systems handle roasting, mixing, rolling, cutting, and cooling.

- Each batch is tested for moisture (<3%), microbial load, and texture stability.

4. Packaging & Labelling

- Chikkis are packed in metalized or nitrogen-flushed laminates, labeled with your brand identity.

- Barcode, nutrition panel, and FSSAI details are integrated as per compliance.

5. Dispatch & Distribution

- Final products are carton-packed, sealed, and dispatched to your distribution or warehouse location.

The manufacturer manages end-to-end traceability, so you can track every batch from production date to retail shelf.

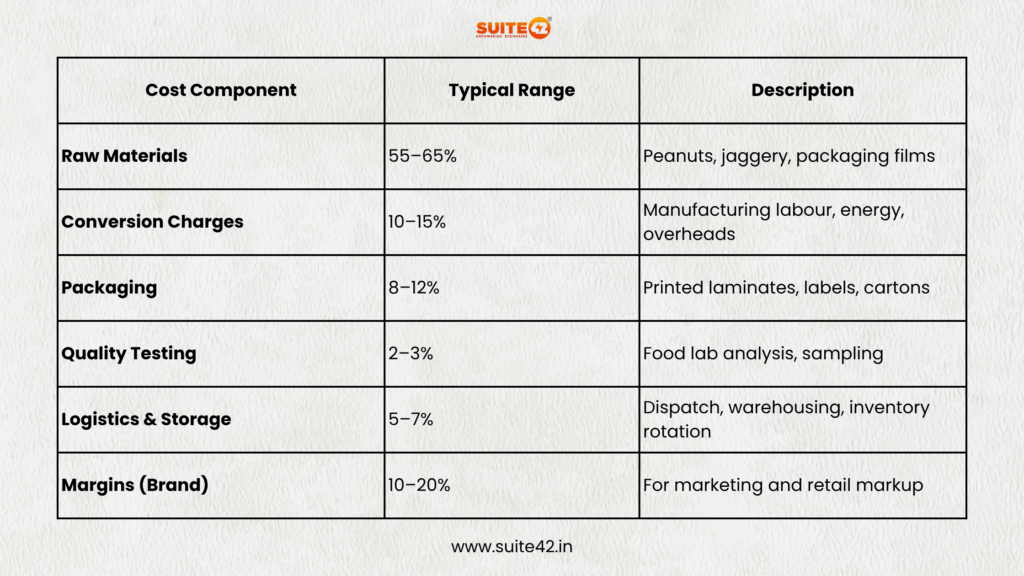

Cost Factors to Consider in Contract Manufacturing

Understanding cost structure helps in pricing your product right.

While the per-kg rate varies depending on volume, packaging, and complexity, these are the major cost heads:

Brands can lower cost per unit by committing minimum order quantities (MOQ) of 1–3 metric tons per variant per month.

Pro Tip: Always finalize costing after pilot batch trials, as actual yield and wastage ratios differ from lab formulations.

Quality & Compliance in Partner Selection

Not every manufacturer meets the hygiene and consistency standards needed for premium snack brands.

When shortlisting contract manufacturers for chikki, check for the following:

- Certifications:

Ensure a valid FSSAI license, ISO 22000, or HACCP certification. - Facility Hygiene:

Visit the production floor – look for stainless-steel equipment, temperature control, pest-proofing, and segregated zones for roasting, mixing, and packing. - Batch Traceability:

The manufacturer should maintain production logs and retain samples for each batch. - Lab Testing Tie-ups:

Confirm partnerships with NABL-accredited food labs in India for quality validation. - Process Note Adherence:

Ensure your recipe and process notes are followed strictly – especially heating temperature, cooling time, and cutting size. - Scalability:

The partner should be capable of increasing volumes quickly to meet market demand spikes without compromising quality.

Choosing the right partner determines not just product quality but also brand reputation and repeat sales.

Case Studies: Successful Peanut Chikki Brands in India

1. Modern Trade Private Label Brand (Confidential Client)

A regional grocery chain wanted to introduce a premium jaggery-based snack under its in-house label.

Suite42 supported formulation, packaging design, and contract production. Within 6 months, the brand achieved placement in 200 stores and reduced production cost by 28%.

2. Health Snack Startup – Protein-Fortified Chikki

An early-stage D2C brand sought to develop a protein-enriched chikki bar.

Through Suite42’s R&D support and pilot trials, the brand created a 12 g-protein bar using peanut and pea protein, wrapped in high-barrier laminate for a 6-month shelf life. The launch attracted 2.5× repeat orders on Amazon within three months.

3. Export-Focused Manufacturer

A manufacturer in Gujarat leveraged Suite42’s compliance guidance to meet Middle East food-safety standards, adding aflatoxin and migration testing.

The result: a stable export SKU with a 9-month life and access to Middle East markets.

These examples show how outsourcing to specialized partners shortens timelines and improves both quality and profitability.

Why Suite42 is a Preferred Partner for Chikki Development

- R&D & Product Formulation: from traditional peanut-jaggery profiles to innovative functional variants.

- Pilot & Commercial Manufacturing: automated lines with real-time QC monitoring.

- Ingredient Sourcing: verified peanut and jaggery suppliers across India.

- Quality & Shelf-Life Testing: through partner food labs for consistent results.

- Packaging Innovation: laminates and formats tailored to your brand positioning.

- Regulatory Compliance: ready for FSSAI, ISO, and export documentation.

Whether you’re launching a new chikki brand or scaling an existing line, Suite42 acts as your manufacturing backbone and R&D engine so you can focus on branding and growth.

Check out our Categories: Bar Categories

Frequently Asked Questions (FAQs)

1. What is peanut chikki contract manufacturing?

It means outsourcing the entire production process – from sourcing ingredients to packaging – to an approved food manufacturer that operates under FSSAI standards.

2. Why should a startup choose peanut chikki contract manufacturing over its own setup?

It eliminates heavy CAPEX, reduces time-to-market, and ensures professional quality control without hiring technical staff or building a factory.

3. What are the minimum order quantities (MOQs)?

Most chikki manufacturers in India start at 1–3 MT per month per variant, depending on packaging type and line capacity.

4. How do I ensure my recipe remains confidential?

Use a Non-Disclosure Agreement (NDA) and provide a written process note approved only for your production batches. Reputed partners like Suite42 follow strict confidentiality protocols.

5. Are contract manufacturers responsible for FSSAI licenses and testing?

The manufacturer handles facility licensing and QC testing. Your brand must hold a marketing license and ensure label compliance under FSSAI regulations.

6. What does a typical peanut chikki factory setup include?

Core equipment includes a roaster, syrup kettle, mixer, roller, cutter, cooling conveyor, and flow-wrap machine, all of which are made of stainless steel to maintain hygiene and efficiency.

7. How does Suite42 ensure quality in outsourced manufacturing?

Through standardized process notes, on-site audits, batch traceability, and NABL-accredited testing, Suite42 maintains consistent quality and compliance across all production partners.

An article that might interest you: How to Ensure Quality & Shelf Life in Peanut Chikki Manufacturing

Final Takeaway

For modern F&B brands, peanut chikki contract manufacturing isn’t merely outsourcing – it’s a smart, scalable business model for growth.

By choosing the right partner, you gain speed, quality assurance, and technical expertise without the burden of infrastructure.

Partner with Suite42 to turn your recipe into a retail-ready product – from formulation to mass production – and enter the market with confidence.

Learn more about Suite42

Leave a Reply