Peanut Chikki Product Development in India: From Recipe Trials to Commercial Scaling

Introduction

India’s snack landscape is evolving fast – and so is consumer preference. While global trends push for protein bars, natural ingredients, and minimal processing, one traditional Indian snack quietly meets all three: Peanut Chikki. A clean-label combination of peanuts and jaggery, it offers high protein, natural sweetness, and nostalgic comfort. For F&B entrepreneurs and food consultants, peanut chikki represents a rare opportunity, a product that bridges heritage and health, tradition and trend. In this blog, we’ll break down the entire peanut chikki product development journey in India, from recipe trials and lab standardization to packaging, shelf-life testing, and commercial-scale manufacturing – so you can transform a simple sweet into a modern, scalable FMCG brand.

An article that might interest you: India’s Potential in the Bars Industry: Manufacturing Capabilities and Export Opportunities

Why Peanut Chikki Is India’s Evergreen Snack Opportunity

India’s traditional snack segment is transforming. Amid the rise of protein bars and clean-label treats, peanut chikki has quietly maintained its relevance. The blend of peanuts, jaggery, and nostalgia gives it a permanent place in Indian households and now, an emerging spot in the health snack and export markets.

For F&B entrepreneurs, this is more than a sweet story. It’s a commercial opportunity. With the right product development process, peanut chikki can evolve from a cottage-scale item to a national-level FMCG product with modern packaging, nutritional positioning, and longer shelf life.

The First Step in Peanut Chikki Product Development – Recipe Standardization & Lab Trials

Before large-scale production begins, every successful peanut chikki brand perfects its recipe formulation. Consistency is everything; the ratio of peanuts to jaggery, caramelization temperature, and final texture determine consumer acceptance.

Key lab trial activities include:

- Ingredient selection & supplier testing – Ensure peanut grade (40–50 count) uniformity and jaggery purity.

- Batch testing – Small-scale cooking (1–5 kg) to evaluate taste, texture, binding, and brittleness.

- Sensory evaluation – Color, flavor, and aroma profiling for consumer appeal.

- Stability sampling – Store samples for 7–30 days under ambient conditions to note moisture absorption and stickiness.

Tip for F&B entrepreneurs: Keep documentation of every trial batch – this becomes your process note for pilot-scale replication.

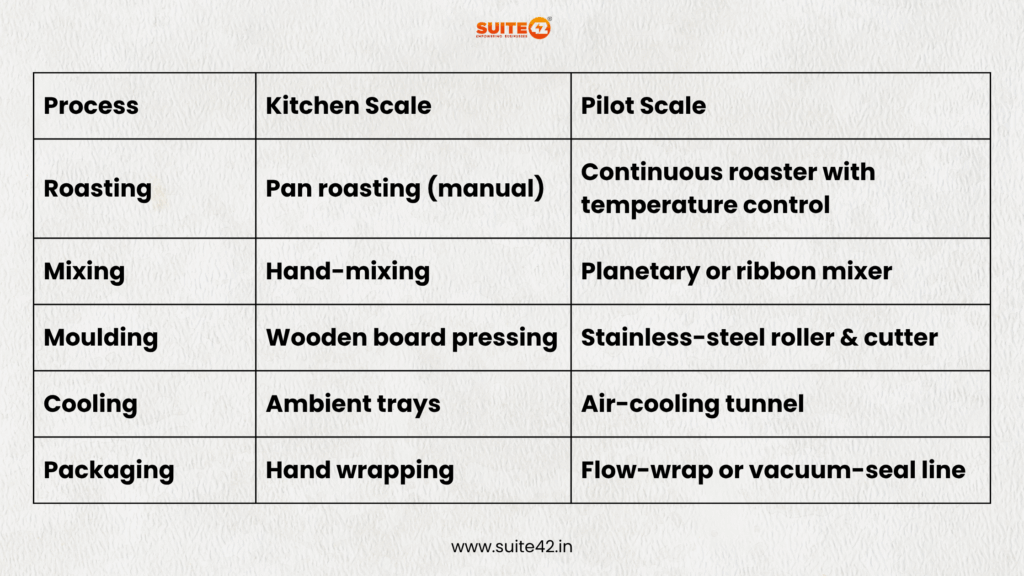

Scaling from Kitchen to Pilot Plant

Once the recipe is standardized, the next step in peanut chikki product development is pilot production. Here’s what typically changes when moving from a 5 kg trial to a 50 kg pilot batch:

The goal is to replicate the same texture and flavor achieved in trials while improving production efficiency and hygiene. Pilot batches also help determine throughput capacity and raw material conversion ratios, both crucial for costing.

Ensuring Quality & Shelf Stability in Peanut Chikkis

Chikkis absorb ambient moisture easily, causing them to lose crunch. Therefore, quality testing and shelf-life validation are essential before launch.

Core stability factors:

- Moisture content: Should remain below 3% to prevent stickiness.

- Water activity (aw): Maintain < 0.5 for optimal shelf stability.

- Packaging material: Use metalized BOPP or PET with low moisture transmission.

- Microbial load: Conduct standard plate count and yeast/mould testing at 0, 30, and 60 days.

Testing is usually performed through NABL-accredited food labs in India. Entrepreneurs who skip this step often face product recalls due to moisture-induced spoilage.

Packaging Innovations for Peanut Chikki Products

The packaging evolution in the traditional snack space is driving premiumization.

Modern peanut chikki packaging must meet four functional goals: protection, shelf appeal, portion control, and sustainability.

Popular formats include:

- Single-serve pillow packs (18–25 g) for retail counters and institutional sales.

- Zipper pouches (150–200 g) for family packs.

- Protein-fortified bars wrapped in metalized laminates for health-food aisles.

- Compostable or paper-laminated wraps for eco-conscious brands.

Smart packaging – paired with desiccant inserts – can extend shelf life by 30–40 days and help brands enter modern trade and export channels.

Commercial Manufacturing – How Contract Partners Like Suite42 Help

Many founders struggle to set up in-house facilities due to high machinery CAPEX, compliance demands, and limited technical expertise. That’s where contract manufacturing becomes the smarter route.

Suite42 supports entrepreneurs through an end-to-end product development to the manufacturing process, including:

- Pilot trials with process optimization

- Ingredient sourcing and vendor audits

- Quality assurance (FSSAI/ISO standards)

- Scalable commercial production with transparent costing

- Packaging development and dispatch management

For startups, this model saves ₹20–50 lakh in upfront setup and ensures faster market entry.

Machinery & Process Flow in Chikki Production

A typical industrial line for commercial peanut chikki manufacturing involves:

- Peanut Roaster → 2. De-sheller & Grader → 3. Syrup Kettle →

- Mixer & Batch Former → 5. Roller & Cutter → 6. Cooling Conveyor → 7. Packing Line

Every stage needs temperature and time calibration to maintain the same brittleness and shine as a handmade chikki – but with industrial precision.

Raw Material Procurement & Supply Chain

The strength of a peanut chikki brand lies in ingredient consistency. Sourcing and logistics directly impact quality, cost, and shelf stability.

1. Peanut sourcing:

Most food manufacturers prefer Saurashtra (Gujarat) or Anantapur (Andhra Pradesh) peanuts due to their uniform kernel size and high oil content. Ensure each batch undergoes aflatoxin testing, especially for export markets.

2. Jaggery quality:

Use light-coloured organic jaggery blocks with low sulphur content and standardize syrup Brix level (120–125°C) to maintain crunch without caramel bitterness.

3. Supply chain:

Adopt First-In-First-Out (FIFO) tracking and temperature-controlled storage. For scale, tie up with suppliers offering consistent grade and price protection across seasons.

Suite42’s sourcing network connects F&B founders with vetted, FSSAI-compliant raw material suppliers, ensuring stability in both quality and cost.

Market Launch & Distribution Strategy

Once the product and packaging are finalized, focus shifts to go-to-market readiness.

Entrepreneurs often underestimate the difference between making a chikki and building a scalable snack brand.

Go-to-market steps:

- Regulatory readiness: FSSAI registration, batch coding, nutrition panel compliance.

- Brand positioning: Highlight “clean jaggery,” “protein-rich,” or “palm oil-free” USPs.

- Channel testing: Begin with modern trade and online marketplaces.

- Sampling and feedback loop: Gather shelf stability and texture feedback post-retail exposure.

- Data-driven scaling: Use secondary sales data and sensory panels to tweak product versions for region-wise preferences.

Brands that adopt a lab-to-market loop (testing–launching–refining) scale faster and maintain consistency, especially under India’s humid climate conditions.

Check out our Categories: Bar Categories

Why Suite42 Is the Right Partner for Peanut Chikki Product Development

From ingredient optimization to co-manufacturing, Suite42 acts as the R&D and manufacturing backbone for emerging snack brands in India.

Our expertise covers:

- Product ideation and recipe formulation for clean-label and functional snacks.

- Pilot and commercial manufacturing with food-lab precision.

- Quality and shelf-life testing support with trusted lab partners.

- Packaging innovation and vendor development for modern trade readiness.

Whether you’re developing a traditional peanut chikki or innovating a protein-enriched, palm-oil-free variant, Suite42 provides the technical foundation to scale confidently.

Frequently Asked Questions (FAQs)

1. How do I start peanut chikki product development for my brand?

Begin peanut chikki product development with recipe standardization and lab trials. This involves defining your peanut–jaggery ratio, testing batches for taste, texture, and shelf life, and documenting every process note. Once validated, move to pilot-scale trials before full commercial production.

2. What is the ideal shelf life for peanut chikki products?

A well-packaged chikki has a shelf life of 3–6 months, depending on moisture control and packaging material. Maintaining water activity below 0.5 and using metalized BOPP films or vacuum sealing significantly extends freshness.

3. Can peanut chikki manufacturing be outsourced?

Yes. Many F&B entrepreneurs use contract manufacturing partners like Suite42 to manage production, quality, and compliance without investing in their own facility. This model reduces CAPEX and speeds up market entry.

4. Which packaging formats work best for peanut chikki?

Single-serve pillow packs (18–25 g) and zipper pouches (150–200 g) are most common. Modern brands also use protein-bar-style flow wraps or compostable paper laminates for premium positioning.

5. How can I improve the quality and consistency of my peanut chikki?

Focus on uniform peanut size, controlled jaggery temperature (120–125 °C), and hygienic stainless-steel mixing equipment. Implement routine moisture and microbial testing through accredited food labs.

6. What are the regulatory requirements for selling peanut chikki in India?

You need an FSSAI license, compliant labeling with nutrition panels, and batch coding. For exports, additional checks like aflatoxin testing and country-specific packaging compliance apply.

7. How does Suite42 help in peanut chikki product development?

An article that might interest you: Pioneering Bars Development Innovation: From Concept to Shelf

Final Takeaway

Peanut chikki may be India’s simplest sweet, but its commercial success depends on scientific precision – in formulation, quality control, and packaging design.

With India’s healthy snack market expanding rapidly, now is the best time to transform this humble sweet into a nationally scalable product.

Leave a Reply