Demystifying US Food & Beverage Regulations for Contract Manufacturing

Navigating the Maze: Understanding US Food Safety Regulations for Contract Manufacturers

The US food and beverage industry thrives on innovation and global partnerships. Contract manufacturing allows brands to leverage expertise and resources around the world. However, navigating the complex landscape of US food safety regulations can be daunting for both US brands and international contract manufacturers. This blog post will serve as your guide, demystifying US food safety regulations for contract manufacturing and highlighting how Suite42 can simplify the process.

Why It Matters: Ensuring Consumer Safety and Business Growth

Food safety is paramount. Stringent US regulations exist to protect consumers from foodborne illnesses. Compliance is not just about avoiding legal repercussions; it’s about building trust with your customers. Partnering with a contract manufacturer that prioritizes food safety allows you to focus on product development and market expansion, confident that your products meet the highest standards.

Article that might interest you: Navigating the US Supply Chain for Food & Beverage Contract Manufacturing.

Understanding the Regulatory Landscape

The Food Safety Modernization Act (FSMA) is the cornerstone of US food safety regulations. FSMA focuses on preventing contamination rather than reacting to outbreaks. Key FSMA rules impacting contract manufacturing include:

- Preventive Controls for Human Food: This rule mandates that all food facilities establish and implement a written food safety plan to identify and mitigate hazards throughout the food production process.

- Foreign Supplier Verification Program (FSVP) for Importers: This rule applies to US importers who are responsible for verifying that their foreign suppliers comply with US food safety standards.

Partnering for Compliance: Shared Responsibility Between Brands and Contract Manufacturers

Compliance is a shared responsibility. US brands are accountable for the safety of their products, regardless of where they are manufactured. Contract manufacturers must demonstrate robust food safety programs to ensure their products meet US standards. Open communication and collaboration are crucial for a successful partnership.

Food Safety Management Systems: The Bedrock of Compliance

A robust food safety management system (FSMS) is the foundation for compliance. Here are some popular FSMS options:

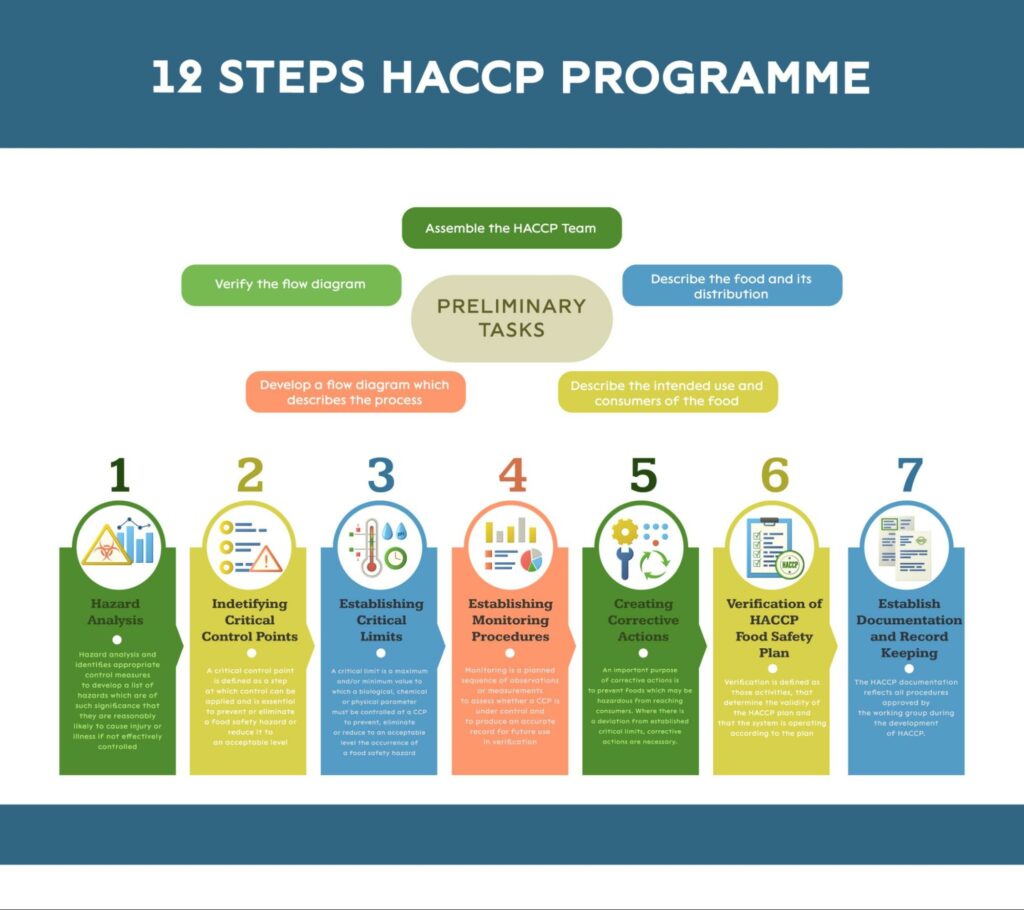

- HACCP (Hazard Analysis and Critical Control Points): The gold standard, HACCP focuses on identifying and controlling critical points in the production process where contamination is most likely to occur.

- SQF Certification: This rigorous program requires a comprehensive food safety management system and independent audits.

- ISO 22000 Certification: This internationally recognized standard provides a framework for building a robust FSMS.

Contract Manufacturing Considerations

Selecting the right contract manufacturer is crucial. Here’s what to consider:

- Pre-Qualification: Evaluate a contract manufacturer’s food safety programs. Look for a documented FSMS, relevant food safety certifications, and a proven track record of compliance.

- Ongoing Communication: Maintain open communication throughout the manufacturing process. Regular audits and clear documentation ensure transparency and timely identification of potential issues.

Article that might interest you: Ensuring Quality and Safety: A Guide to Food Contract Manufacturing in the USA.

Essential Compliance Components for Contract Manufacturers

- Food Safety Certification: Demonstrate your commitment to food safety through independent certification.

- Food Traceability: Implement a robust traceability system to track ingredients and products throughout the supply chain. This is crucial for effective recall management.

- Food Production Inventory Management: Maintain control of raw materials and finished products. Effective inventory management minimizes the risk of contamination and facilitates targeted recalls if necessary.

Suite42: Your Gateway to US-Compliant Contract Manufacturing

Partnering with Suite42 simplifies US contract manufacturing. Here’s how:

- Pre-Vetted Network: Connect with a network of Indian and global contract manufacturers pre-vetted for US compliance. This saves you time and resources spent on qualification.

- Streamlined On-boarding: Reduce the time and resources needed for on-boarding a contract manufacturer. Suite42 streamlines the process, ensuring a smooth transition.

Compliance Expertise: Leveraging Suite42’s Knowledge of US Regulations

Suite42’s team of experts can guide you through the intricacies of US food safety regulations. We provide:

- FSMA Compliance Guidance: Ensure your contract manufacturing partnership meets all FSMA requirements.

- Transparency Throughout the Supply Chain: Gain clear visibility into your contract manufacturer’s food safety practices through Suite42’s platform.

Suite42: Your Partner in US Contract Manufacturing Success

Suite42 is your one-stop shop for successful US contract manufacturing. We offer a comprehensive suite of services designed to streamline the process and ensure compliance. Here’s what sets us apart:

- Industry Expertise: Our team has deep experience in US food safety regulations and the contract manufacturing landscape.

- Technology-Driven Platform: Our platform simplifies communication, streamlines on-boarding, and provides real-time visibility into your supply chain.

- Global Network: Connect with a vast network of pre-vetted contract manufacturers worldwide, ensuring you find the perfect partner for your needs.

The Path to Successful US Contract Manufacturing

Building a successful US contract manufacturing partnership goes beyond regulatory compliance. Here are key considerations:

- Collaborative Relationship: Foster open communication and a shared commitment to food safety. Regular communication allows for proactive problem-solving and continuous improvement.

- Investing in Food Safety: View food safety as a strategic advantage, not just a cost. A strong food safety culture attracts reputable partners and builds consumer trust.

- Continuous Improvement: Embrace a culture of continuous improvement in food safety practices. Regular audits, employee training, and investment in new technologies ensure ongoing compliance and minimize risks.

Conclusion

Safeguarding the food supply chain is a shared responsibility. By understanding US food safety regulations and partnering with a compliant contract manufacturer, US brands can expand their reach with confidence. Suite42 simplifies US contract manufacturing by connecting you with pre-vetted partners and providing expert guidance on navigating the regulatory landscape.

Resources for Contract Manufacturers: Tools and Support for Success

The FDA website is a valuable resource for contract manufacturers seeking information on US food safety regulations: https://www.fda.gov/

Additionally, industry associations such as the Grocery Manufacturers Association (GMA) offer resources and support for contract manufacturers: https://www.gmabrands.com/

By leveraging these resources and partnering with Suite42, contract manufacturers can ensure they are well-equipped to meet the demands of the US market.

Leave a Reply